Science & Technology

Explore Our Science & Technology

Visionary Gene-Based Solutions Fueled by Innovative Manufacturing Technologies

Lacerta Therapeutics is deploying proprietary AAV capsid variants and a state-of-the-art manufacturing platform to support its growing therapeutic pipeline. These innovative technologies are available for licensing, and we are aggressively seeking partnerships to further enable the development of AAV gene therapies for patients.

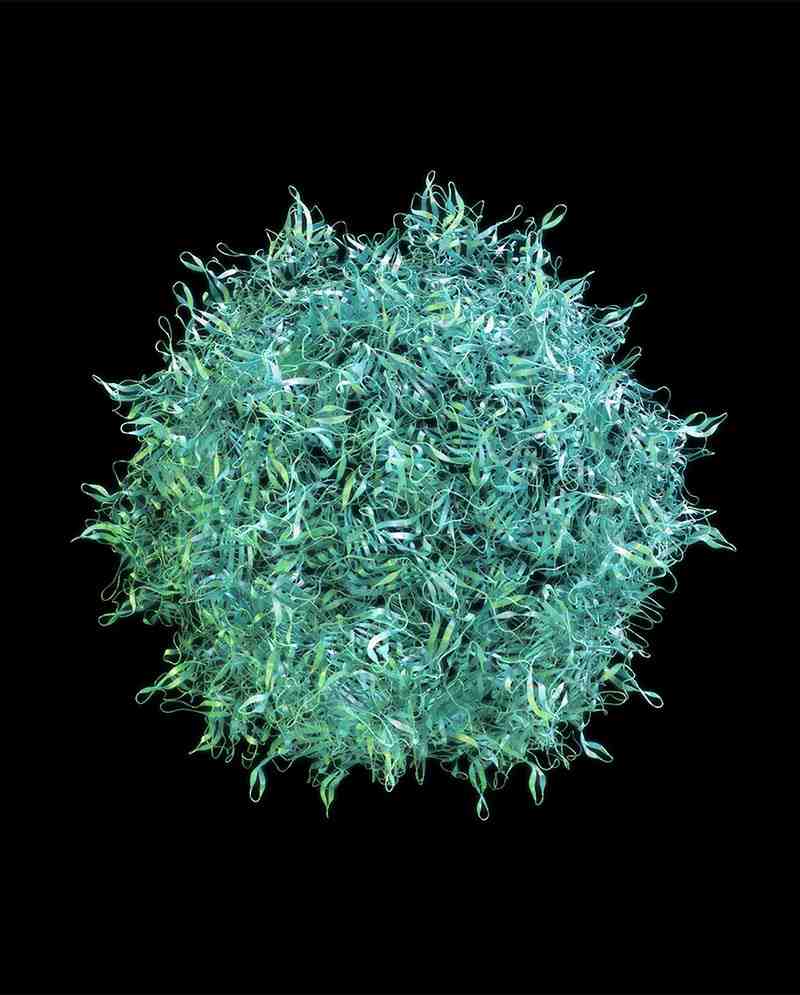

AAV CAPSID ENGINEERING PLATFORM

Lacerta Therapeutics has established an innovative AAV capsid engineering platform that combines rational design and combinatorial libraries approaches to derive novel AAV capsid variants for our CNS and lysosomal storage disease applications.

Read More

By targeting specific surface exposed residues and/or randomizing subsets of surface variable regions, we have developed a catalogue of novel AAV capsid variants with improved transduction profiles for all naturally occurring serotypes tested to date. The production of these novel AAV capsid variants has been validated in our proprietary AAV vector manufacturing platform using both packaging and producer cell line strategies.

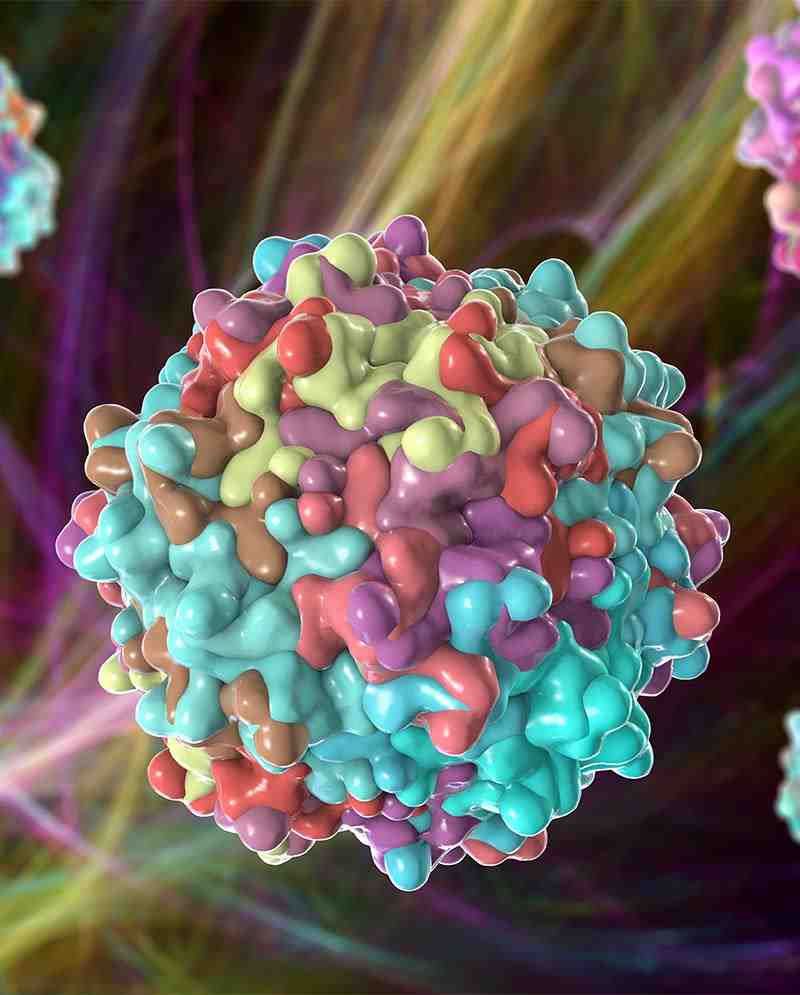

AAV VECTOR MANUFACTURING PLATFORM

Lacerta Therapeutics has developed a robust AAV vector manufacturing platform using next-generation stable packaging and producer insect cell lines to generate high AAV vector yields using a single baculovirus (OneBac).

Read More

Using novel expression control elements, the OneBac platform employs baculovirus-inducible expression of critical AAV helper functions to produce AAV vectors and extends the utility of the insect cell/baculovirus system to all AAV vector serotypes and capsid variants. The platform is modular and flexible allowing for the choice of stable AAV packaging insect cell lines carrying AAV Rep and Cap or AAV producer insect cell lines that carry all required AAV components. These high stable cell lines are capable of high yield AAV vector production following infection with a single gene of interest or wildtype baculovirus, respectively. OneBac overcomes numerous issues related to AAV production in insect cells including inconsistent infection efficiencies related to the use of multiple baculoviruses, stability problems related to passage expansion of certain AAV helper baculoviruses, the requirement for inducible expression of AAV helper functions to establish stable packaging cell lines, and extends the system to all AAV serotypes through the identification of serotype specific Kozak sequences that produce appropriate capsid protein stoichiometry for effective vector production. Expression of AAV helper proteins is induced upon baculovirus infection with a feed-forward loop amplification of the integrated helper genes leading to AAV vector burst sizes per cell exceeding those of all other platforms. The OneBac platform provides a lower cost, more scalable alternative to conventional plasmid transfection and other infection based AAV manufacturing approaches.

AAV VECTOR MANUFACTURING PLATFORM

Lacerta Therapeutics has developed a robust AAV vector manufacturing platform using next-generation stable packaging and producer insect cell lines to generate high AAV vector yields using a single baculovirus (OneBac).

Read More

Using novel expression control elements, the OneBac platform employs baculovirus-inducible expression of critical AAV helper functions to produce AAV vectors and extends the utility of the insect cell/baculovirus system to all AAV vector serotypes and capsid variants. The platform is modular and flexible allowing for the choice of stable AAV packaging insect cell lines carrying AAV Rep and Cap or AAV producer insect cell lines that carry all required AAV components. These high stable cell lines are capable of high yield AAV vector production following infection with a single gene of interest or wildtype baculovirus, respectively. OneBac overcomes numerous issues related to AAV production in insect cells including inconsistent infection efficiencies related to the use of multiple baculoviruses, stability problems related to passage expansion of certain AAV helper baculoviruses, the requirement for inducible expression of AAV helper functions to establish stable packaging cell lines, and extends the system to all AAV serotypes through the identification of serotype specific Kozak sequences that produce appropriate capsid protein stoichiometry for effective vector production. Expression of AAV helper proteins is induced upon baculovirus infection with a feed-forward loop amplification of the integrated helper genes leading to AAV vector burst sizes per cell exceeding those of all other platforms. The OneBac platform provides a lower cost, more scalable alternative to conventional plasmid transfection and other infection based AAV manufacturing approaches.